The evolving Kaveri Derivative Turbofan Engine

Initial Prithvi missiles were laughed at and derided. We persisted and now have the Agni series with 8000km+ Agni 6, MIRV capability included. Akash Air defence missiles started on similar note, today many countries wish to purchase it.

Akash 2 and Akash 3 will soon form the backbone of our missile defence shield. Arjun Mk2, Pinaka 2, Astra series, Vishakhapatnam class destroyers, Nigeria class frigate etc all are similar success stories.

We did not persist with HF24 Marut and because of it lost valuable decades.

Tejas jet fighter we persisted and now we have Mk1A, Mk2 and moving to AMCA, TEDBF etc.

The Kaveri engine has been facing a similar set back for long. However now light can be seen at the end of the tunnel. We persisted despite everyone laughing ….mostly Indians. Instead Kaveri, the Kaveri Derivative Engine and the advanced Kaveri 2.0, are all strategic, long-term indigenous engine development programs that will soon start to support self-reliance goals in jet fighters.

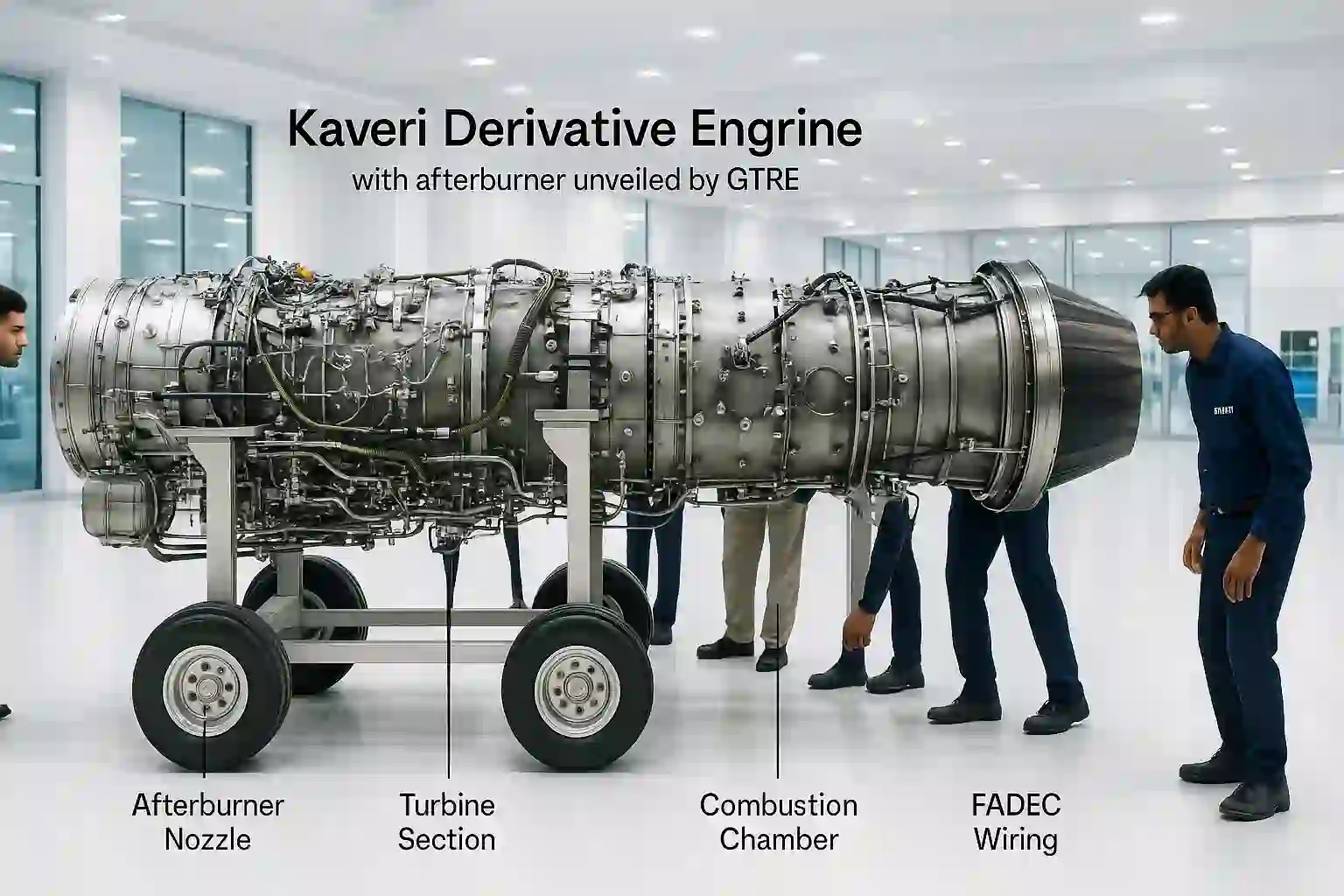

Kaveri Derivative Engine (KDE), developed by India’s Gas Turbine Research Establishment (GTRE), is the next version of the original GTX-35VS Kaveri turbofan engine. It is already producing 49- 51 KN of thrust. This will now be used for unmanned combat aerial vehicles (UCAVs) and other platforms including MiG21s turned into UCAVs.

The KDE is being further developed with an afterburner module capable of producing around 73–74 kN of wet thrust, that is, as good as the French Safran M88-2 engine (≈75 kN) powering Rafale jets.

However, it needs to catch up with the General Electric F404-IN20 engine, which powers the TEJAS MK-1A and produces about 54 KN dry thrust and 84 kN wet thrust. Then we can have the Tejas MK1B fitted with our own desi engines.

Meanwhile HAL will continue with GE F404- IN20 engines due to the complexities and extensive re-certification effort needed to change engines on the already manufactured MK-1A airframe. However, since GE cannot supply more than 24 engines per year, a parallel line should be started, as soon as possible for 16 x Tejas Mk1 B per year.

For this the KDE needs to be integrated, tested, and optimised specifically for the MK-1A airframe, ensuring full operational capability and certification. As per current plan the KDE will definitely be fitted on MKA1 during mid-life upgrades or replacements around 2035. By that time the engine’s maturity and reliability will be fully proven.

Next goal for us is Kaveri 2.0 engine version with thrust levels of 90 to 100 kN to power TEJAS MK-2 and Advanced Medium Combat Aircraft (AMCA).So we do have about 5 years time.

Thus the work on Kaveri has certainly not been a waste. In fact cost wise it has been akin to our Chandrayaan and Mangalyaan missions when compared to NASA’S missions.